Perforated sound - absorbing panels

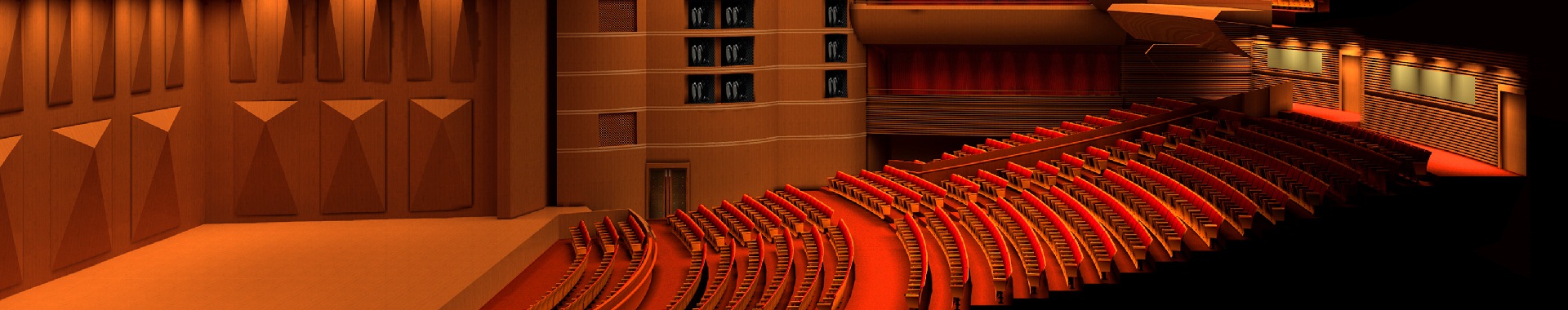

Wood hole acoustic board is a front and back are perforated wooden sound-absorbing panels, positive aperture is greater than the back of the aperture. The sound can pass through the back hole through the front hole. Circular sound-absorbing wood acoustic board in accordance with the principle of rational and reasonable, with excellent noise reduction performance, on the high-frequency sound absorption effect is particularly good. Commonly used in stadiums, hotels, exhibition halls, school lecture halls, performing arts centers, conference rooms and other places of the walls and smallpox.

Technical Parameters

1. Structure: substrate, finishes, back

2. Substrate: pottery aluminum plate, glass magnesium board, red glass magnesium board, red flame retardant board, medium density fiberboard, moisture board, bamboo board, common board

3. Finishes: melamine, natural veneer, paint

4. Back: black sound-absorbing stick

5. Conventional specifications: 600 * 600mm, 600 * 1200mm, 800 * 600mm, 800 * 1200mm, 1200 * 1200mm, 1200 * 2400mm

6. Conventional thickness: 12/15 / 18mm

7. Conventional pore size: 1,2,3,4,5,6,8,10,12 mm and so on

8. Conventional styles: 8/8/1, 16/16/3, 16/16/6, 32/32/6, 32/32/8

9. Sound absorption band: full-frequency absorption

10. Formaldehyde emission: According to GB18580-2001 "indoor decoration materials, wood-based panel and its products in the formaldehyde emission" test, formaldehyde emission of E1 level.

11. Fire rating: According to GB8624-2006 "Classification of building materials and products combustion performance" test, combustion performance of A1 / A2 level.

installation

.

(A) of the pre-installation and installation requirements of the place: (with slot wood sound-absorbing panels)

(B) installation

1. Measure the wall size, confirm the installation location, determine the horizontal and vertical lines, determine the wire socket, pipe and other objects cut space reserved size.

2. According to the actual size of the construction site calculation and cut some sound-absorbing panels (opposite the symmetry requirements, in particular, pay attention to the size of some sound-absorbing panels cut to ensure that the two sides of the symmetry) and lines (edge lines, outer lines, Lines), and for the wire socket, pipe and other objects cut blank reserved.

3. Installation of sound-absorbing panels:

(1) sound-absorbing panels installed in order to follow from left to right, from bottom to top principles.

(2) sound-absorbing panels installed in horizontal, the notch up; vertical installation, the notch on the right.

(3) part of the wood sound-absorbing panels are on the pattern requirements, each facade should be prepared in accordance with the sound-absorbing plate number in advance from small to large in order to install. (Sound-absorbing plate number from left to right, from bottom to top, the number followed by small to large)

4. Sound-absorbing panel in the keel on the fixed:

(1) Wood keel: with the shoot installation along the mouth and the mouth of the board slot with the nail will be fixed in the acoustic board keel, nail must have more than 2/3 embedded wood keel, nail to be evenly arranged, and require A certain density, each sound-absorbing panels and each keel on the number of connected nail not less than 10.

(2) light steel keel: the use of special installation accessories

The sound-absorbing panels are mounted horizontally with the notches facing up and mounted with mounting accessories, each of which is in turn connected.

The sound-absorbing panels are mounted vertically, with the notches on the right, and are installed from the left in the same way. If the installation of large area, two sound-absorbing panel side to stay out of the gap is not less than 3mm.

Technical Parameters

1. Structure: substrate, finishes, back

2. Substrate: pottery aluminum plate, glass magnesium board, red glass magnesium board, red flame retardant board, medium density fiberboard, moisture board, bamboo board, common board

3. Finishes: melamine, natural veneer, paint

4. Back: black sound-absorbing stick

5. Conventional specifications: 600 * 600mm, 600 * 1200mm, 800 * 600mm, 800 * 1200mm, 1200 * 1200mm, 1200 * 2400mm

6. Conventional thickness: 12/15 / 18mm

7. Conventional pore size: 1,2,3,4,5,6,8,10,12 mm and so on

8. Conventional styles: 8/8/1, 16/16/3, 16/16/6, 32/32/6, 32/32/8

9. Sound absorption band: full-frequency absorption

10. Formaldehyde emission: According to GB18580-2001 "indoor decoration materials, wood-based panel and its products in the formaldehyde emission" test, formaldehyde emission of E1 level.

11. Fire rating: According to GB8624-2006 "Classification of building materials and products combustion performance" test, combustion performance of A1 / A2 level.

installation

.

(A) of the pre-installation and installation requirements of the place: (with slot wood sound-absorbing panels)

(B) installation

1. Measure the wall size, confirm the installation location, determine the horizontal and vertical lines, determine the wire socket, pipe and other objects cut space reserved size.

2. According to the actual size of the construction site calculation and cut some sound-absorbing panels (opposite the symmetry requirements, in particular, pay attention to the size of some sound-absorbing panels cut to ensure that the two sides of the symmetry) and lines (edge lines, outer lines, Lines), and for the wire socket, pipe and other objects cut blank reserved.

3. Installation of sound-absorbing panels:

(1) sound-absorbing panels installed in order to follow from left to right, from bottom to top principles.

(2) sound-absorbing panels installed in horizontal, the notch up; vertical installation, the notch on the right.

(3) part of the wood sound-absorbing panels are on the pattern requirements, each facade should be prepared in accordance with the sound-absorbing plate number in advance from small to large in order to install. (Sound-absorbing plate number from left to right, from bottom to top, the number followed by small to large)

4. Sound-absorbing panel in the keel on the fixed:

(1) Wood keel: with the shoot installation along the mouth and the mouth of the board slot with the nail will be fixed in the acoustic board keel, nail must have more than 2/3 embedded wood keel, nail to be evenly arranged, and require A certain density, each sound-absorbing panels and each keel on the number of connected nail not less than 10.

(2) light steel keel: the use of special installation accessories

The sound-absorbing panels are mounted horizontally with the notches facing up and mounted with mounting accessories, each of which is in turn connected.

The sound-absorbing panels are mounted vertically, with the notches on the right, and are installed from the left in the same way. If the installation of large area, two sound-absorbing panel side to stay out of the gap is not less than 3mm.